GF Flow Building Solutions: Decades of reliability for professionals – 30 years with Uponor Quick & Easy

30 years with Uponor Quick & Easy

In 1994, Uponor set a milestone in the HVAC industry with the introduction of the Quick & Easy system. By utilizing the unique material properties of PEX-a pipe, it was possible to create pipe connections that were stronger than the pipe itself – a groundbreaking innovation for installers worldwide. Three decades and over 500 million fittings sold later, Uponor Quick & Easy remains the preferred choice of professionals who value ease of installation and exceptional durability.

In 1972, Uponor (now GF Building Flow Solutions) launched the world’s first PEX pipes on the market, revolutionizing an entire industry. The plastic pipe system for drinking water and heating installations meets all the requirements for hygienic installations. Made of high molecular polyethylene plastic, the pipes do not release any taste, odor, heavy metals or substances into the drinking water; the durable material is not affected by high flow speed or water with a low pH value. The memory effect and the high resilience of the pipes form the basis for Uponor Q&E (Quick & Easy) connection technology, with which Uponor set a new standard for pipe connections in 1994.

Innovative connection technology with minimal installation effort

With Uponor Quick & Easy, the name says it all, because the fittings are connected to the pipe in three simple steps: Expand the pipe and the fitted Q&E ring. The expanded pipe is then pushed onto the end of the fitting. The final step is performed by the material itself; the connection is made in seconds as the pipe is shrinking. “Our Uponor Q&E fittings require no solder, torches, fluxes or solvents for the installation. The pipes’ unique shape memory forms a tight seal around the fitting, creating a strong, reliable connection in seconds,” says Charlotta Persfell, Chief Marketing Officer, GF Building Flow Solutions. “And with minimal effort, saving installation time and costs.”

The combination of the unique jointing technologies and the proven performance of the Uponor PEX pipes is one of the reasons for the success of the PEX pipe system around the globe. Charlotta Persfell says: “In North America, Uponor is recognized as a leader in flexible polymer piping solutions with the industry’s most tested, listed, and code-approved PEX piping product on the market. Based on the same principle of PEX expansion connection like Q&E, the jointing system ProPEX® compliant to F1960 standard provides pipe connections our customers rely on for decades.”

Ongoing product development as part of the success story

Driven by the ongoing pursuit of innovation, GF Building Flow Solutions continuously invests in the development of its solutions, introducing new features and improvements based on customer feedback and market requirements. “In 2023, we launched the world’s first bio-based PEX pipe1 and with this, reducing the carbon footprint up to 90% compared to fossil-based PEX pipes,“ says Charlotta Persfell. “With this product we have made a major step forward to serve the emerging need of

sustainable construction, supporting our customers to make sustainable choices, set new standards and achieve their environmental goals. “

Customer satisfaction that convinces – for 30 years

With over 500 million fittings sold, Uponor Quick & Easy is one of the systems that professionals rely on when it comes to reliable, easy-to-install and durable pipe connections. “Our proximity to our specialist partners and their practical expertise are key drivers for our product development. The positive feedback from our specialist partners confirms our commitment to products that enable efficient, safe and stress-free installation,” says Charlotta Persfell.

Alberto Tejero from Istalaciones (Spain) says: “For over 20 years, we have relied on Uponor’s Quick & Easy system for our installations. The system’s speed, cleanliness, and safety – especially compared to our previous work with copper – have made it our preferred choice. The flexibility of the pipes, along

with a wide range of accessories, allows us to work even in hard-to-reach spaces.”

Sig. Halvorsen from Sandnes (Norway) says: “We’ve relied on the Quick & Easy system since 1998,

initially choosing it for its safer connection technology compared to the commonly used screwed

systems of the time. What stands out to us is the system’s reliability – leaks are rare, and the design

makes incorrect installation nearly impossible, ensuring safety on every project.”

Advantages of the Uponor Q&E system at a glance:

• Proven quality: Known for reliability and innovative performance for over 30 years

• Strong connections: Permanent tightness thanks to the memory effect of PE-Xa pipes

• Easy installation: Significantly reduced installation time and costs

• Long-lasting: No pitting, scaling or corrosion

• User-friendly and safe: Low-error, self-explanatory system, no O-rings or other movable parts,

reducing risks of leakages, no solder, torches, fluxes or solvents required for the installation

• Versatile: Suitable for water and heating installations in residential, commercial and industrial

buildings

Beulco: New EU Drinking Water Directive – challenges and opportunities for manufacturers and users

New EU Drinking Water Directive and Positive List of Materials: Stricter lead limits and lead-free materials – challenges and opportunities for manufacturers and users

The European Commission is committed to continuing to ensure the supply of high-quality drinking water, taking into account the latest scientific recommendations. Therefore, the European Drinking Water Directive (TWR) 2020 was revised. The new revised TWR 2020/2184 came into force in 2021 and was to be implemented in all EU member states by January 12, 2023.

The update of the Drinking Water Directive mainly focuses on materials that come into contact with drinking water. The changes relate to current quality standards for microbiological, chemical and indicator parameters. These include new requirements for lead concentration. The permissible lead concentration has been reduced from the current 10 µg/l at the tap to 5 µg/l. These parameters must be met by January 2036. Germany has decided to incorporate the new parameters into the Drinking Water Ordinance already, so that the values will become mandatory from 2028, and only components that come into contact with drinking water and are made of such a material may be sold and installed.

In addition, the European Chemicals Agency (ECHA) has created an EU positive list of materials. This list defines hygiene requirements for products that come into contact with water, such as pipes and fittings, and works in conjunction with Article 11 of the Drinking Water Directive. The list specifies which materials can be used.

With the introduction of the new EU positive list of materials, the EU is taking a significant step towards ensuring drinking water hygiene. This list includes numerous materials and products for use in drinking water systems and aims to protect water quality and consumer health.

Both regulations work together to reduce the lead content in materials and drinking water.

© BEULCO

What does this mean for distributors and customers?

BEULCO recommends that affected companies adjust their product portfolio of corresponding products by the end of 2026. This enables a timely conversion to compliant materials and provides sufficient leeway to offer compliant products for installation by 2028. For many companies, this means a fundamental revision of their product range and production processes. The changeover to lead-free materials is not only necessary to comply with the regulations, but also puts the companies placing the products on the market in a future-proof position, especially with regard to possible future regulations that could assess lead limits and mass fractions even more strictly.

From 1 January 2028, only compliant products may be installed in the installations. From 2026, new approval seals are expected to come onto the market, which will supplement or replace the existing seals such as DVGW and KIWA.

In response to these developments, BEULCO started to switch to the lead-free material CW724R (Cuphin/ Ecobrass) and to adapt its product range accordingly more than 10 years ago. In 2026, the entire portfolio of products for applications in contact with drinking water will consist of lead-free alternatives. In addition to CW724R, other lead-free alloys and alternatives are also being tested.

The conversion to lead-free materials is of the utmost urgency in view of the stricter EU regulations. Companies that do not meet the new limit values in time risk not only considerable legal and financial consequences, but also a competitive disadvantage. Compliance with the new requirements requires an early adaptation of the production processes and a strategic realignment of the product portfolio.

BEULCO provides comprehensive information on this topic on its website and is available to assist both distributors and users of products containing lead with its expertise.

EU legislation | The significance for the lead processing industry | BEULCO

REHAU: The new sustainable universal pipe RAUTITAN flex green saves 90% CO2

Sustainable construction is not only becoming ever more important but is also increasingly becoming the norm. The new drinking water and heating pipe, RAUTITAN flex green can save more than 90% CO2 in the manufacturing process. It is based on renewable, bio-based raw materials and can help to achieve sustainability targets.

RAUTITAN flex green is a drinking water and heating pipe made of PE-Xa. What makes it special is that the plastic is made from renewable, biocircular raw materials. For example, vegetable fats are used, which are produced as waste and by-products in the food industry. External and independent certification by ISCC Plus ensures that the proportion of renewable raw materials can be tracked transparently along the value chain. ISCC Plus (International Sustainability & Carbon Certification) is a global certification program with the aim of establishing sustainable raw material chains.

RAUTITAN flex green is a drinking water and heating pipe made of PE-Xa. What makes it special is that the plastic is made from renewable, biocircular raw materials. For example, vegetable fats are used, which are produced as waste and by-products in the food industry. External and independent certification by ISCC Plus ensures that the proportion of renewable raw materials can be tracked transparently along the value chain. ISCC Plus (International Sustainability & Carbon Certification) is a global certification program with the aim of establishing sustainable raw material chains.

The polyethylene used is mass-balanced and consists of 100% renewable, biocircular raw materials. © REHAU

The polyethylene used is mass-balanced and consists of 100% renewable, biocircular raw materials. This means that the production of RAUTITAN flex green saves more than 90% CO2 compared to standard fossil based PEX pipes on the market.

The new RAUTITAN flex green offers the same benefits as the tried and tested RAUTITAN flex:

- Just as clean: The lead-free RAUTITAN flex green pipe system is hygienically optimised for drinking water installations. The smooth inner pipe walls and excellent impermeability of the cavity-free jointing technology effectively prevent contamination.

- Just as flexible: RAUTITAN flex green is highly unlikely to buckle, especially in the case of small pipes. Despite this, the pipe is flexible: you can easily bend it over your thumb without any tools, even at low temperatures.

- Just as reliable: RAUTITAN flex green achieves a permanently leak-tight connection with fittings and compression sleeves. The pipe itself is the sealant, with no O-rings and no manual labelling.

The pipe is made of high-performance PE-Xa plastic and contains a special oxygen diffusion barrier – making it suitable for both drinking water installations and heating. RAUTITAN flex green complies with DIN EN ISO 15875 and is oxygen-tight in accordance with DIN 4726. It can be used universally for drinking water and heating installations and is compatible with the REHAU RAUTITAN system of pipes, fittings, sliding sleeves and tools.

Contact: REHAU Industries SE & Co. KG, Germany, www.rehau.com

SANHA wall heating module demonstrates specific advantages

© Sanha

Wall heating systems are among the most efficient types of heat transfer. As surface heating, they are extremely well suited for combination with heat pumps, for example. In contrast to comparable systems, SANHA wall heating modules offer the advantage that they can provide heat both in the low temperature range and up to 60 °C. In addition, they are much easier to install. They are also much easier to install.

An old building in the south of Essen is currently being fitted with wall heating modules. This is an example of how our systems can demonstrate their advantages and support energy-efficient refurbishment at the highest level in a technology-neutral way.

© Sanha

The building, built in 1977, is currently undergoing a comprehensive energy refurbishment. This includes efficient façade insulation as well as a modern heating system based on natural gas condensing heating. A total of two floors with five rooms (one downstairs, four upstairs) are to be heated. The calculated heating load of the upper floor (85 m²) is around 2.5 kW (assuming 30 K to the outside temperature), which is optimally provided by wall heating modules, while the first floor is supplied with heat via underfloor heating.

The client opted for SANHA® wall heating modules primarily because of their high flexibility. The maximum heat output is up to 210 W/m², which is higher than comparable products. This means that wall heating modules can be operated very efficiently in the low temperature range during the transitional period and still use the high possible flow temperatures of the natural gas heating system on particularly cold days.

Another reason why the client chose SANHA® wall heating modules was the ease of installation: using a mounting rail and dowels, they are much easier to install than underfloor heating, for example; there is no need for labor-intensive ripping up of the floor and subsequent re-installation, drying times for the screed, etc. – a clear advantage.

Added to this was the fact that neither the wall heating modules nor the underfloor heating generate any convection or dust: “As an allergy sufferer, this aspect was very important to me,” says the client. The upper floor, which is particularly exposed to the sun on hot days, can also be cooled by the wall heating modules if necessary. This is particularly true for a studio with high ceilings.

Dew point undercutting and mold prevention

Wall heating also makes sense when it comes to preventing mold on the walls. Mold develops when water vapor from the air condenses on colder objects, i.e. when the temperature falls below the dew point (or dew point temperature). The type of ventilation also plays a role: it is better to ventilate several times a day than to keep the window tilted. Conventional convection heating systems cannot prevent moisture loss or condensation in every situation, as the warm air collects on the ceiling and sinks downwards after cooling – and can provide an ideal breeding ground for mold in the cooler areas of the wall.

@ Sanha

Wall heating works on the principle of the sun

Wall heating, on the other hand, does not primarily heat the air, but warms objects and people through heat radiation – similar to the sun. This is not only perceived as very pleasant, but also ensures lower humidity. In addition, this type of panel heating does not cause any draughts or swirling up of dust. Conventional radiators, on the other hand, lead to the air movement described above, which is caused by layers of different temperatures. For ideal protection against mold growth, operation at a minimum temperature of 16 °C is advisable (climatic conditions in Central Europe; the dew point can shift under very cold or very dry climatic conditions).

Room heating and cooling

With the wall heating module, SANHA® provides a system for room heating and cooling (room heating) that is characterized in particular by exceptional living comfort, very simple installation, significantly better energy efficiency due to a lower average room temperature and particularly health-friendly properties. This system is ideal for both new buildings and the renovation of existing buildings.

Wall heating modules are supplied ready to use with a surface that can be painted or wallpapered directly. The SANHA® wall heating module is a prefabricated element that is installed in a similar way to a panel radiator. It consists of a galvanized sheet steel frame in which a multi-layer composite pipe (PE-RT/AL/PE-RT) is inserted and enclosed with a special heating mortar. The element is encased in cardboard paper. The maximum heat output is up to 210 W/m², which is higher than comparable products.

Notes on storage and transportation

The SANHA® wall heating modules must be treated similarly to drywall panels on the construction site, i.e. protected from moisture in particular. The modules must not be placed on the connecting pipes. The modules are delivered on pallets. When transporting individual modules, bending must be avoided. They must therefore be transported on edge. There is a banderole with corresponding instructions on each module. This label must be removed during assembly.

Contact: www.sanha.com

HeatExpo in Dortmund/GER: Inaugural 3-day show proved tremendously successful

![]()

EATEXPO, a new European trade show covering all topics associated with the move to renewable heating, was held at Messe Dortmund between 21 and 23 November 2023 / High satisfaction among organisers, exhibitors and visitors to the new B2B forum covering all aspects of the move to renewable heating / HEATEXPO 2024: November 26-28.

KWD-globalpipe, 01.12.2023. With a consistent focus on the heating sector, the HEATEXPO 2023 presented a 360-degree environment with innovative technologies, new products and services for sustainable and innovative heating solutions. The focus was on local & district heating, gas and elec-tricity as well as heating and cooling networks.

The exhibiting companies came from the fields of pipe systems, plant engineering, equipment manufacturing, technology, project development, infrastructure, services and consulting. Around 100 exhibitors were present at the premiere of the new trade fair, companies from twelve countries with their solutions and technologies – including Sweden, Finland, Italy, Belgium, the Netherlands, Austria and the USA.

In this issue of KWD-globalpipe you will find exhibitor reports from the companies BRUGG Pipes, Danfoss, ENERPIPE, ISOPLUS, Kingspan LOGSTOR, REHAU, THERMAFLEX and Uponor.

(If you are interested to read it, please send an email to hix@kwd-online.de with the subject “Send free copy of KWD-globapipe 903).

From the perspective of everyone involved, the new B2B show immediately managed to fill a gap and establish itself as a new forum for dialogue on all topics related to the move to renewable heating. There are many reasons for this success: the contributions of the partners involved, the comprehen-sive, informative supporting program and the opportunity at the venue to find out about new trends, technologies and solutions for tomorrow’s heating.

Above all, it was an unusually small but pleasant trade fair: One exhibition hall, many small exhi-bition

All Fotos: HIX Publishing, Jutta Hix

stands, intensive discussions were held everywhere and the supporting program with lectures, workshops etc. was quite well received. Organisers, exhibitors and visitors were all up-beat about the new show, and many have already confirmed their participation next ye

Contact: HeatExpo, Messe Dortmund /DEU, www.heat-expo.de.

FRÄNKISCHE: alpex F50 PROFI® multilayer composite pipe system for more than 20 years

Safety and durability, easy installation and utmost hygiene: FRÄNKISCHE is a pioneer in the field of installation systems and has been on the market with its alpex multilayer composite pipe systems for heating and drinking water installations for more than 20 years.

Safety and durability, easy installation and utmost hygiene: FRÄNKISCHE is a pioneer in the field of installation systems and has been on the market with its alpex multilayer composite pipe systems for heating and drinking water installations for more than 20 years.

@ FRÄNKISCHE

Permanent temperature resistance, crimp jaw flexibility and lead-free design have been standard features for alpex F50 PROFI and alpex-duo XS for many years. Along with multilayer composite pipes in the dimensions from 16 to 32 mm, the systems also include a great variety of fittings – for maximal flexibility at the construction site.

FRÄNKISCHE answers the most important questions to offer its users the best possible and practical support:

- Up to which temperature can alpex F50 PROFI and alpex-duo XS be used?

- How are direction changes realised and which bend radii are possible?

- Are the alpex F50 PROFI and alpex-duo XS fitting systems lead-free?

- How is the insertion depth checked?

- How can one tell if the alpex F50 PROFI and alpex-duo XS systems have been securely installed?

- Is it necessary to perform deburring and calibration during installation?

- How does the installation system ensure the highest drinking water hygiene?

- How do the alpex F50 PROFI / alpex-duo XS systems ensure regular water exchange and reliable operation?

- Can the alpex systems be directly connected to heat pumps?

@ FRÄNKISCHE

Is implementing riser pipes with multilayer composite pipes economically reasonable?

The answers to the questions can be found on the website of Fränkische Rohrwerke:

https://www.fraenkische.com/en/news-item/alpex-f50-profi-r-wissenswertes-fuer-installateure?context=

Source: Fränkische Rohrwerke Gebr. Kirchner GmbH & Co. KG, www.frankische.com.

Photos: Fränkische Rohrwerke

KWD Market+Charts Report: Impact of declining housing completions

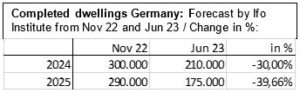

At its summer conference in June, Euroconstruct published the latest projections for housing completions. These are now significantly lower than expected at last winter conference in 2022.

![]()

The headline of the official Euroconstruct report of the summer conference in June of this year already suggests a falling housing construction forecast: ” Risks and uncertainties impeding the growth of the European construction market”. Even clearer is the headline of the press release of the German ifo Institute related to the situation in Germany: “Significantly fewer new homes by 2025”!

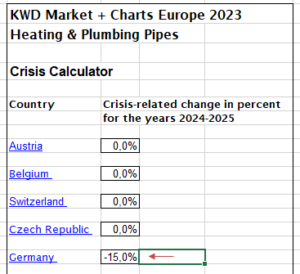

Already at the beginning of the year, when preparing the current KWD Market + Charts study with the forecast for pipe consumption for surface heating, radiator connection and sanitary installation, we considered a worsening of the construction completion figures as a possibility. So, we have again included the Crisis Calculator to our market report.

The Crisis Calculator is intended to provide a way to respond to increased construction interest rates, high realization costs and economic slowdown in the new construction market. With its help, every user of our market study can react individually to changes by adjusting the forecasts for 2024 and 2025 by means of a percentage input per country.

For the current situation in Germany, the crisis calculator can show the new residential construction situation as follows:

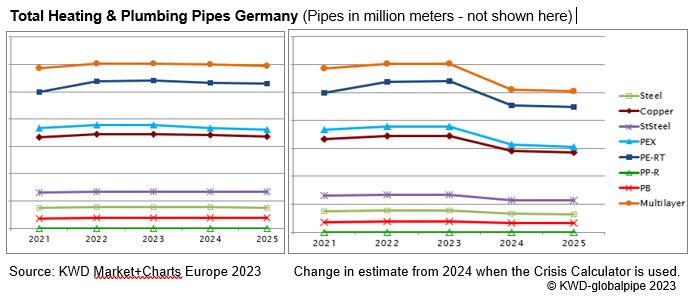

The KWD Market +Charts study is based on the forecast from the ifo Institute from Nov. 2022. However, as can be seen in the table on the right, the expected housing completions in Germany shrink drastically in the new forecast: 30% in 2024 and almost 40% in 2025.

However, it must also be seen

- 7hat subsidies for modernization projects have been raised sharply and that the modernization market should therefore grow.

- and also in the new construction sector, the heat pump and thus frequently surface heating systems will play a much stronger role.

We will now simply assume a possible decline of 15% in pipe consumption in 2024 and 2025 in Germany as an example. The situation would then be as follows:

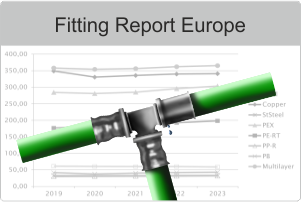

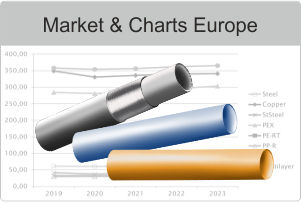

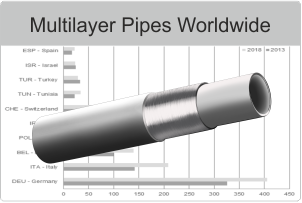

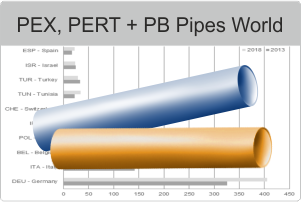

The report KWD Market + Charts “Heating & Plumbing Pipes Europe 2023” estimates how many million meters of pipe have been or will be installed in domestic plumbing systems in Europe and lists them by pipe material and application per EC19 country.

The KWD report costs 1,200 euros for our subscribers and 1,450 euros for all others (in Germany plus VAT, abroad with advance payment). Authors are Jutta Hix, chief editor of the KWD information services and Achim Seydel of Seydel Consulting. Detailed information about the study with page examples and order forms are attached to this issue.

More Info: https://www.globalpipe.de/market-reports/on-heating-plumbing-pipes/

Contact: HIX Publishing, hix@kwd-online.de.

Jansen expands production capacity and focuses on sustainable energy generation

![]()

Jansen expands production capacity and focuses on sustainable energy generation

Jansen Plastics offers a wide range of extruded plastic solutions characterised by Swiss quality, reliability, safety and economy. These are used in the areas of water management, building services, geothermal energy and specific customer profiles. Jansen has long-standing expertise in multi-layer and multi-component extrusion. Now the possibilities for producing composite pipes for a wide range of applications are being expanded.

Major investment in innovative multi-layer pipe production plant

As the most innovative supplier of technically sophisticated composite pipe solutions, Jansen is investing the impressive sum of around CHF 5.0 million in the most modern, interlinked multi-layer pipe production plant. The new plant has an annual capacity of over 17 million metres. The integrated laser welding system no longer requires welding electrodes; as a result, the heat impact on the material is lower and butt welding is more reliable.

In addition to the technical advantages, a local partner was chosen in order to lend holistic weight to the issue of sustainability. The composite pipe system opens up new production possibilities in the field of geothermal energy for the JANSEN hipress geothermal probe, the strongest geothermal probe in the world, and the PRIMA pipe range for the high-temperature range with drinking water approval. This also includes the PE-RT aluminium composite pipe made of temperature-resistant polyethylene with an aluminium layer.

Sustainability: major investment in solar energy

In March, the contract for the construction of a new 2.1 MWp photovoltaic plant was awarded; it is one of the largest plants in the region of Eastern Switzerland. Back in 2009, the largest PV system in the region at the time was installed on one of the production halls. In 2022, another followed with an output of 608 kWp. In the next few years, more roofs are to be covered with PV modules.

With these investments, Jansen is promoting its sustainable development with the future aim of increasingly producing the necessary energy for its production operations itself, or to be as energy self-sufficient as possible in the future.

HPG plastics becomes part of the HULIOT Group: Bundled competence

The German specialist for PE-RT pipes joins the international Huliot Group.

The Huliot Group, a global company with over 750 employees, is successfully continuing its expansion course in Germany with the acquisition of hpg plastics gmbh. With this step, the Huliot Group is primarily strengthening its expertise in the field of surface heating systems.

Since 1984, hpg plastics gmbh has specialized in the production of PE-RT pipes for surface heating, drinking water systems and sanitary applications. The portfolio mainly includes the production of innovative pipes such as the extremely flexible “Flexolen®”, the safe “Inverse®”, or the completely customizable “Composite®”.

The aim of the acquisition is to offer existing and potential customers of both companies an even more comprehensive range of services covering the complete spectrum of pipe systems globally. This strong collaboration will enable a wide range of innovative solutions to be offered from a single source.

As a result of the takeover, the Huliot Group will grow to around 800 employees at its locations in Israel, India, Slovenia, Portugal and Germany. At the same time, hpg plastics gmbh will remain unchanged as a subsidiary at the site in Ratingen/Germany. The CEO of hpg plastics gmbh, Jürgen Hendrikx, will also remain part of the team as Managing Director, helping to ensure the efficient integration of services and knowledge: “We are delighted that together with the Huliot Group we now have the opportunity to continue our growth globally, develop synergies with other group members and expand our product range.”

Huliot Group is a global leader in advanced flow systems for commercial & residential buildings, bringing complete solutions that cover water supply, wastewater, & infrastructure. Huliot was established in 1947 by the members of Kibbutz Sde Nehemia in Israel’s Upper Galilee. Since 2019 Huliot Group is jointly owned by Kibbutz Sde Nehemia (50%) and the Tene Investment Fund (50%).

CEO Huliot Group Nitzan Cohen (left) and CEO hpg plastics Jürgen Hendrikx at the fair ISH Frankfurt 2023

CEO Huliot Group Nitzan Cohen (left) and CEO hpg plastics Jürgen Hendrikx at the fair ISH Frankfurt 2023

Contact: hpg plastics GmbH, Ratingen /DEU, www.hpg-plastics.com / www.huliotgroup.com.

Molecor donates a shipment of pipes and fittings to Turkey to help in the reconstruction of the water infrastructure

The earthquakes registered in the south of Turkey since the 6th of February reached magnitudes of up to 7.7 on the Richter scale and produced devastating effects in the region with a serious impact on the population and the country’s infrastructure.

Molecor, a company dedicated to the manufacture of piping and sanitation products, has sent more than 12km of PVC-O TOM® pipes and ecoFITTOM® fittings for the reparation and installation of drinking water supply networks to help the recovery of the country.

The urgency of the situation has prompted a rapid response from countries, institutions, companies and volunteers to help rebuild the region as quickly as possible. Among the most important tasks are ensuring the safety of all citizens and restoring damaged infrastructure so that affected cities can recover basic services.

Water is a basic necessity for the recovery of Turkey and it is intended that with the help of Molecor and the efforts made by everyone, access to this service can be recovered in the area as soon as possible.

Source: www.molecor.com